Odparky s mechanickou kompresí par H2O

Vakuová destilace se etablovala jako nejhospodárnější metoda zpracování průmyslových odpadních vod rozmanitého původu a poskytuje skutečnou alternativu vůči likvidaci (vyvážení) a jiným způsobům zpracování. Díky naší inovativní špičkové technologii VACUDEST můžete oddělit čistou vodu od Vaší průmyslové odpadní vody. Tak snížíte objem odpadních vod a tím Vám dramaticky klesnou náklady na jejich likvidaci. Upravená voda může být opětovně použita ve výrobě, čímž bude Vaše výroba téměř bez odpadních vod. Tímto přispíváte k udržitelnému využívání zdrojů čisté vody a investujete do čisté budoucnosti.

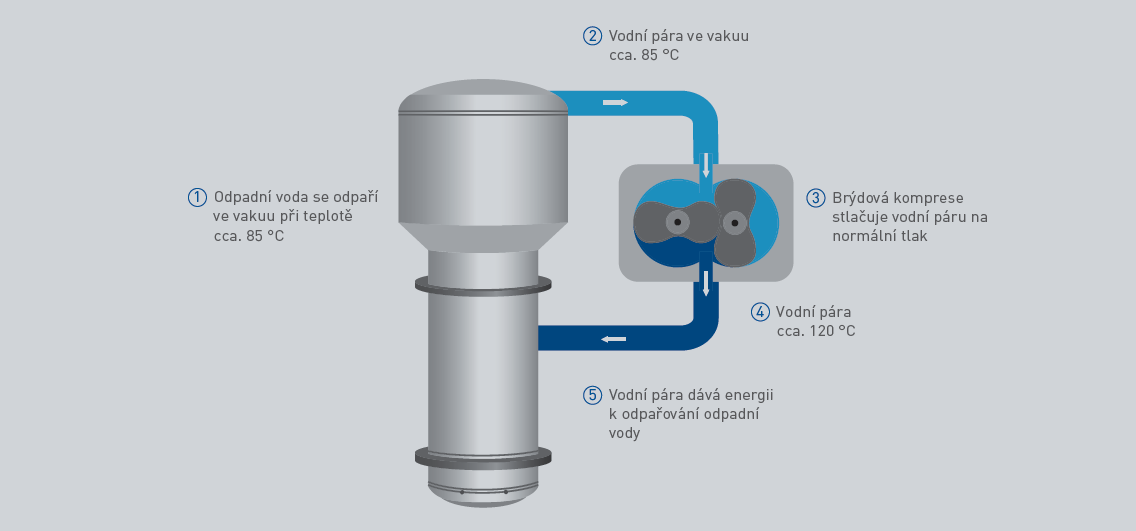

Princip fungování odparky H2O (obchodní označení VACUDEST) je nejlépe vidět z následujícího obrázku:

V zařízení VACUDEST není použit žádný topný element. Naopak je využita několikastupňová rekuperace tepelné energie. Mimo jiné i proto je jeho provoz mimořádně hospodárný.

Přes 30 let nepřetržitého vývoje přináší zákazníkům mnohá pokročilá řešení, která jinde nenajdete. Například náš patentovaný kondenzační stupeň ClearCat umožňuje snížení ukazatele CHSK až o 99 procent.

Obsluha zařízení je nenáročná, jeho provoz je plně automatický.

Oblasti použití

Zařízení VACUDEST dává vynikající výsledky zejména při nasazení v těchto průmyslových odvětvích: Výroba a zpracování kovů, výroba dopravních prostředků, letecký průmysl, strojírenství, elektrotechnika, zpracování odpadních vod.

Typy odpadních vod, které jsou zařízením VACUDEST s úspěchem zpracovávány, uvádíme níže. Seznam není vyčerpávající, ukazuje nejčastější použití.

Odpadní vody s oleji

- Použitá chladící emulze

- Dělící emulze z tlakového lití

- Oplachová voda z čištění/odmašťování dílů

- Oplachová voda ze zkoušky trhlin

- Oplachová voda z čištění obalů – kontejnerů

Odpadní vody se solemi

- Oplachová voda z galvanických procesů

- Oplachová voda z omílání

- Oplachová voda z povrchových úprav před lakováním

- Oplachová voda z moření nerezu

- Průsaková voda ze skládek